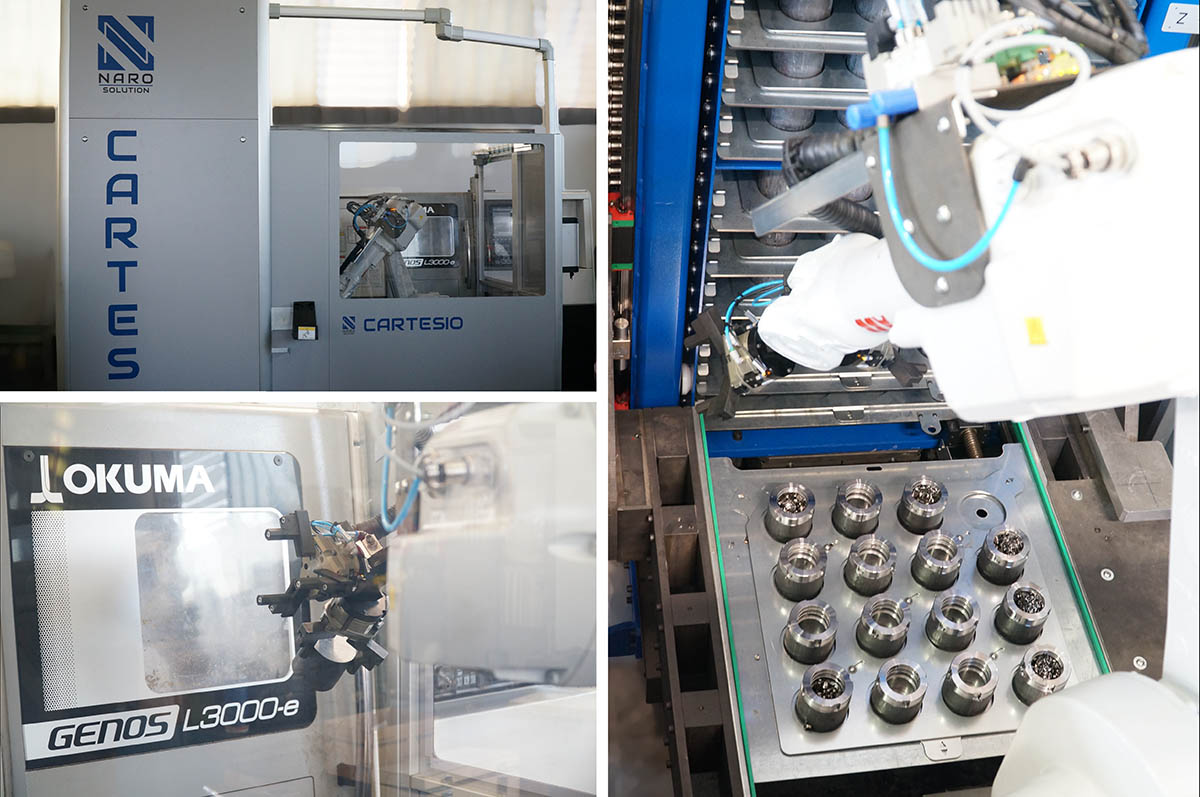

ADVANTAGES:

- Reduced dimensions compared to conventional stations

- Customizable to customer requirements

- Free machine tool front for retooling or maintenance work

- Long autonomy (dependent on cycle time)

- Simple and intuitive operator interface

- Parametric programs reduce set-up times

- Low maintenance and easy retooling